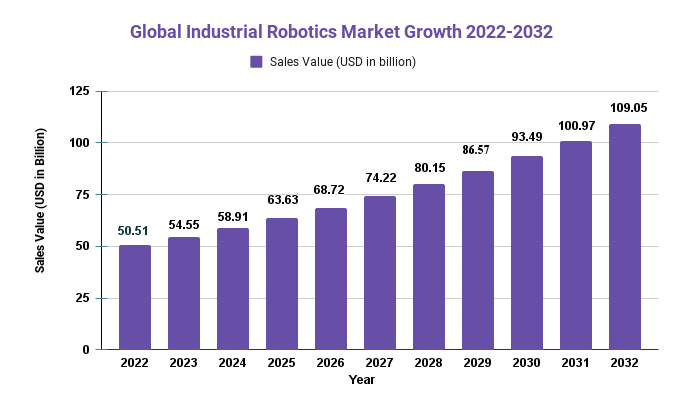

Industrial Robotics Market Share is set to increase by USD 109.5 billion by 2032

Page Contents

Industrial Robotics Market Overview

Published Via 11Press: The industrial robotics market is a rapidly growing industry with no signs of slowing down. In 2022, the global industrial robotics market was valued at USD 50.51 billion and it is expected to reach a value of USD 109.5 billion by 2032, registering a compound annual growth rate (CAGR) of 8% over the forecast period 2022-2032.

An industrial robot is a type of machine that receives data and is programmed automatically to perform tasks related to industry production. The program can be modified and programmed for these robots, according to the application. These robots can be programmed to improve productivity, lower costs, and produce high-quality goods for automation applications. Robots are made up of drives, sensors, actuators, robot manipulators, controllers and end-effectors. Robotic controllers are the brain of the robot that help in the delivery and execution of commands. Robot sensors are made up of microphones and cameras that help keep the robot in touch with its industrial environment.

Robotic manipulator is the robotic arm of the robot that aids in positioning and movement. End effectors are the robot's arms that assist in the interaction with workpieces. There are many types of robots used in the industry, including Cartesian, Collaborative and SCARA robots. The type of robot you choose will depend on the requirements of your work, such as size and payload. For a healthy and efficient production process, industrial robots can optimize it.

The increasing focus on automation in the manufacturing sector and rising labor costs are driving the global industrial robotics market growth. The deployment of advanced robots in industries is helping them reduce operational costs and increase efficiency, thereby improving their overall performance. Additionally, growing demand for automation from food & beverage manufacturers as well as pharmaceutical companies is also driving the growth of this market.

Request For Sample Before Purchasing This Report: https://market.us/report/industrial-robotics-market/request-sample/

Key Takeaways

- The industrial robotics market is driven by factors such as increasing automation in manufacturing processes, rising demand for industrial robots in emerging economies, and advancements in robotic technologies.

- The market is expected to experience significant growth in the coming years, due to the increasing adoption of robots in industries such as automotive, healthcare, and food and beverage.

- Asia Pacific is the largest market for industrial robotics, due to factors such as the growing industrialization and automation of manufacturing processes in countries such as China and Japan.

Regional Snapshots

- The North American industrial robotics market is driven by factors such as the increasing adoption of collaborative robots, the growing demand for robots in the automotive industry, and the increasing use of robots in the healthcare sector.

- European an increasing demand for robots in the manufacturing and automotive sectors, the growing trend of Industry 4.0, and the rising investments in research and development of robotics technologies.

- The increasing adoption of automation and robotics technologies in manufacturing processes, the growing demand for robots in the automotive industry, and the rising investments in research and development of robotics technologies.

- The key contributors to the industrial robotics market include Germany, China and Japan. With a revenue share exceeding 52.0%, the Asia Pacific region was the dominant market. It is expected to maintain its dominance through the forecast period. It also shipped the most units in 2016, with around 151 000 units. The forecast period will see a significant CAGR.

- China, Japan and Korea are the major industrial robot manufacturing centers in Asia Pacific. South Korea and Japan are the leaders in the installation of industrial robots in the region. The booming electronics industry is responsible for the rapid growth of these markets.

Drivers

The Market is Growing because of the Increased Investment in All Industries

- Industrial robots are highly in demand across many industries, including automotive, pharmaceuticals and consumer electronics. However, this depends on the type of robot they will need to place in their areas to increase industrial activity and reduce costs. To increase production flexibility, players in the consumer electronic industry could deploy collaborative robots faster.

- This has led to significant investment in the business which is increasing the demand for these robots. Nissan Motor bought two lines of UR10 collaborative robotics, i.e. Universal Robots provided arms for the Yokohama plant to reduce labor costs and maintain efficiency in manufacturing processes such as Takt Time. The market has also seen growth in pharmaceuticals, electronics and industrial companies.

- In addition to the increasing adoption of EVs, another key driver of the EV charging infrastructure market is the growing demand for fast charging solutions. As consumers become more accustomed to the convenience of on-the-go charging, the need for fast charging infrastructure is increasing. This is particularly true in urban areas where EV drivers need to quickly recharge their vehicles during short stops.

Restraints

High Investments in the Initial Stage and Low Maintenance Costs Hinder Market Growth

- It might prove difficult for organizations without the necessary expertise to make the initial investment. A large capital investment is required for procurement, integration, programming and accessories as well as maintenance. This could impede market growth. Small and medium-sized businesses find it hard to invest large amounts of money due to low volume manufacturing and poor returns on investment.

- The market is also being affected by the recent collapse in the COVID-19 pandemic. The rapid shutdowns of various industrial units and businesses have had a significant impact on overall production and supply chains. On the other side, industrial robot manufacturers are expected to experience a surge in sales and overcome any obstacles that may have resulted from the pandemic.

- In addition to the key drivers, there are also several factors that could restrain the growth of the EV charging infrastructure market. One of the primary restraining factors is the limited driving range of many electric vehicles. Since EVs have a shorter range compared to traditional gasoline vehicles, drivers may be hesitant to purchase an EV if they are concerned about finding a charging station in a timely manner.

- Another potential restraining factor is the lack of awareness and education about EV charging infrastructure. Many consumers and businesses may not fully understand the benefits of EVs and charging infrastructure, which can lead to slower adoption rates and lower demand for charging solutions.

Purchase This Report Via Secured Link and Avail Discount: https://market.us/purchase-report/?report_id=55415

Challenges

Despite the growth opportunities, there are also several challenges facing the EV charging infrastructure market. One key challenge is the lack of standardization in charging infrastructure, which can make it difficult for EV drivers to find a charging station that is compatible with their vehicle. Additionally, the high cost of installing and maintaining EV charging infrastructure can be a barrier for some businesses and municipalities.

Opportunities

Opportunities in Emergence of Industry 5.0

- Industry 5.0 is a new concept. The European Commission states that Industry 5.0 is a vision for industry that goes beyond productivity and efficiency. It also strengthens industry's contribution to society. It puts the welfare of workers at the heart of production and uses new technologies to create prosperity that goes beyond the needs of jobs and growth, while also respecting the limits of the planet's production. Industry 5.0 is a complement to industry 4.0 by putting innovation and research at the service for a European industry that is sustainable, human-centric, and resilient.

- The fifth industrial revolution will include the critical role of industrial robots. They will close the design loop. The entire production process can be fully automated, allowing humans to innovate and create without worrying about production constraints. Industry 5.0, in contrast to Industry 2.0, aims to bring the human touch back to development and production. It will maximize the creativity and intellectual capabilities of humans. The emergence of industry 2.0 will open up a new market for collaborative robots.

Problems: Safety concerns regarding industrial robotics systems

- Industrial robots pose many safety concerns. Robots in traditional industries are often powerful and fast. As a result, there is a greater risk of injury. For example, one swing from a robot arm could cause severe bodily harm. Additional risks exist when a robot is not working properly or needs maintenance. Workers can be injured by a malfunctioning robot because it is often unpredictable. A jammed motor on a robot arm in a car assembly line could cause injury to workers.

- The worker who is trying to fix the problem may be struck by the robotic arm. A worker who is standing in an area that overlaps with nearby robot arms could also be injured by moving equipment. Many Indian companies have reported crushing, trapping and collision accidents as a result of malfunctioning parts of industrial robots. In 2020, a 44 year-old welding worker at Automotive Stampings & Assemblies Ltd. (Asal), Pune (India) was struck on the neck and head by a robotic arm.

Market Key Trends

The global market for electric vehicle (EV) charging infrastructure is expected to experience strong growth in the coming years, driven by a number of key trends. One major trend is the increasing adoption of EVs, which is driving demand for charging infrastructure as more consumers and businesses switch to electric vehicles. This trend is being fueled by government policies and incentives aimed at reducing carbon emissions and promoting sustainable transportation solutions.

Recent development

- February 2020: FANUC and BMW AG have signed a framework deal where FANUC will supply 3,500 robotics to new production lines. These robots will be used in the development of future and existing BMW models.

- March 2020: FANUC has introduced the CRX-10iA, a new collaborative robot. The robot can perform high-functional tasks using a flip motion.

- ABB announced in October 2020 the acquisition of Codian Robotics Netherlands, a leader in delta robots for high-precision pick-and-place applications. Codian Robotics offers a line of hygienic robots that are ideal for use in hygiene-sensitive industries such as food, beverage, and pharmaceuticals. ABB expects to expand its offerings of delta robots with the acquisition.

Market Segmentation

Type

- AGV

- Laser Processing Robotics

- Vacuum Robotics

- Cleaning Robotics

Application

- Construction

- Home Appliances

- Electronic

- Automative

- Food

- Medical

Key Companies

- ABB

- Adept Technology

- Denso Wave

- DURR

- Fanuc

- Kawasaki Heavy Industries

- KUKA

- Nachi-Fujikoshi

- Seiko Epson

- Yaskawa Electric

- Unimation

Report Scope

| Report Attribute | Details |

| Market size value in 2022 | USD 50.51 billion |

| Revenue forecast by 2032 | USD 109.5 billion |

| Growth Rate | CAGR Of 8% |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa, and Rest of the World |

| Historical Years | 2017-2022 |

| Base Year | 2022 |

| Estimated Year | 2023 |

| Short-Term Projection Year | 2028 |

| Long-Term Projected Year | 2032 |

Contact

Contact Person: Mr. Lawrence John

Global Business Development Team – Market.us

Market.us (Powered By Prudour Pvt. Ltd.)

Address: 420 Lexington Avenue, Suite 300 New York City, NY 10170, United States

Tel: +1 718 618 4351

For Sales Inquiries: [email protected]

FAQ.

Industrial robots are used for a wide range of applications, including assembly, welding, material handling, painting, and inspection.

Collaborative robotics, or cobots, are robots that are designed to work alongside humans in a shared workspace. They are often used for tasks such as assembly, packaging, and quality control.

The team behind market.us, marketresearch.biz, market.biz and more. Our purpose is to keep our customers ahead of the game with regard to the markets. They may fluctuate up or down, but we will help you to stay ahead of the curve in these market fluctuations. Our consistent growth and ability to deliver in-depth analyses and market insight has engaged genuine market players. They have faith in us to offer the data and information they require to make balanced and decisive marketing decisions.